VCI (Volatile Corrosion Inhibitor) plastic is an innovative product designed to prevent corrosion in metals during storage and transportation. This special plastic is impregnated with volatile chemical compounds that emit vapours capable of protecting metals from corrosion, even in harsh environments.

Corrosion is a chemical process that affects metals, weakening their structure and decreasing their lifespan. In industrial and logistics environments, where metals are exposed to moisture, temperature changes, and other environmental factors, corrosion can be especially damaging. This is where VCI Plastic comes in.

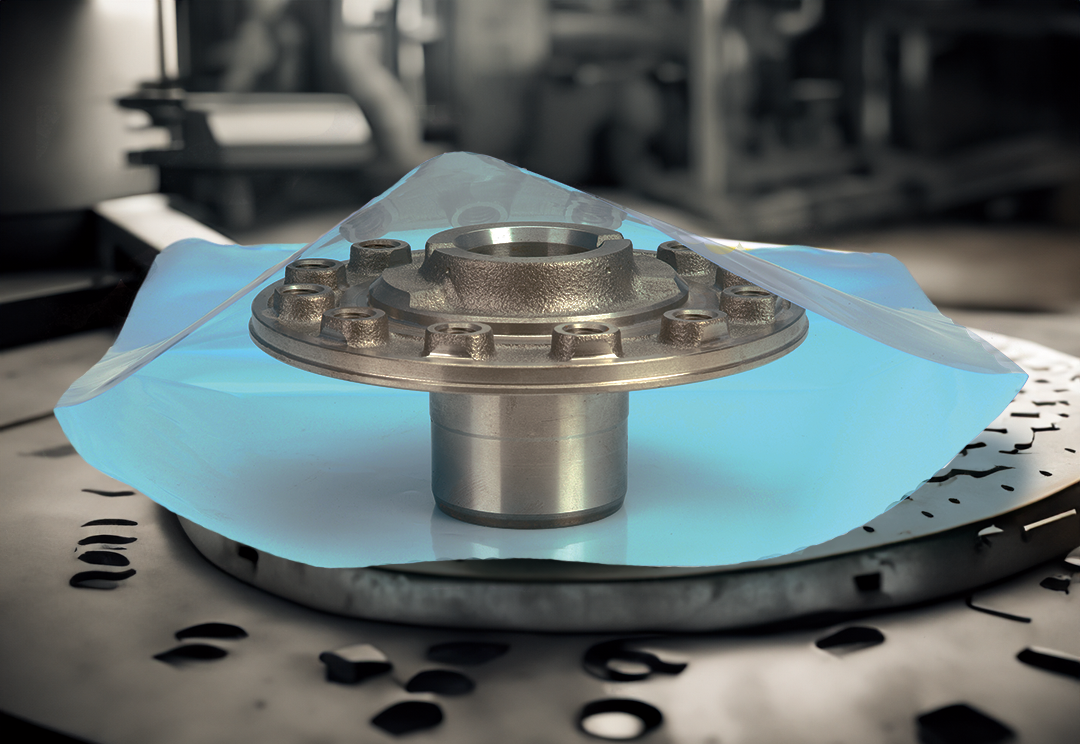

By wrapping or coating metals with VCI Plastic, a protective barrier is created that releases corrosion inhibitors in a controlled manner. These compounds create an invisible layer on the surface of the metal, preventing moisture and contaminants from coming into direct contact with the material. This disrupts the corrosive process by preventing the formation of rust and other degradation products.

VCI Plastic is highly versatile and can accommodate a variety of applications and metal shapes, including machined parts, electronic components, machinery, and tools. It’s ideal for long-term protection, as the inhibitory compounds stay active for months or even years, depending on the conditions.

In addition to its effectiveness in preventing corrosion, VCI Plastic offers economic and environmental advantages. By extending the life of metals and reducing the need for replacement, maintenance and production costs are lowered. In addition, by preventing corrosion, it contributes to the reduction of waste and the more efficient use of resources.

VCI Plastic is used in a variety of industrial and commercial sectors where corrosion protection of metals is crucial. Some of the sectors in which VCI Plastic is used include:

Automotive: In the manufacture and shipping of automotive parts, from engines to electronic components, VCI Plastic is used to prevent corrosion during storage and transportation.

Electronics Industry: It is used to protect electronic components and printed circuits against corrosion in warehouses and during shipping, preventing long-term damage.

Aerospace: Aircraft parts and components can be subject to harsh environmental conditions. VCI Plastic is used to ensure that these parts arrive in optimal condition and without corrosion.

Metallurgical Industry: In both the production and storage of steel, aluminum, copper and other metal products, VCI Plastic protects against corrosion and rust.

Oil & Gas Industry: Equipment and parts used in the exploration, production and transportation of oil and gas are protected with VCI Plastic to extend their service life and reduce maintenance costs.

Naval and Maritime Industry: Marine applications expose metals to highly corrosive environments. VCI Plastic helps protect naval and marine equipment and components.

Contact us and we will offer you a solution adapted to your needs.

Heavy Machinery Industry: Industrial equipment and heavy machinery are often stored and shipped for long periods. VCI Plastic protects these investments from corrosion.

Power Industry: In both electric power generation and the nuclear industry, VCI Plastic prevents corrosion in equipment and components used in these critical applications.

Construction Industry: It is used in the protection of metal elements such as beams, structures and prefabricated parts, preventing corrosion during storage and construction.

Packaging and Storage Industry: VCI Plastic is also used in the manufacture of bags, wraps, and packaging sheets that provide protection to metal products during storage and distribution.

Defense Industry: In the protection of weapons and military equipment, VCI Plastic is essential to maintain functionality and durability.

Railway Industry: In the manufacture and shipment of railway parts and components, VCI Plastic is used to prevent corrosion and maintain structural integrity.

In case this solution does not perfectly fit the needs of your products or services you can always contact us directly and we will be happy to find the best alternative for you.

VCI (Volatile Corrosion Inhibitor) plastic has a number of distinctive features that make it an effective solution for preventing corrosion in metals. Here are some of the key features: