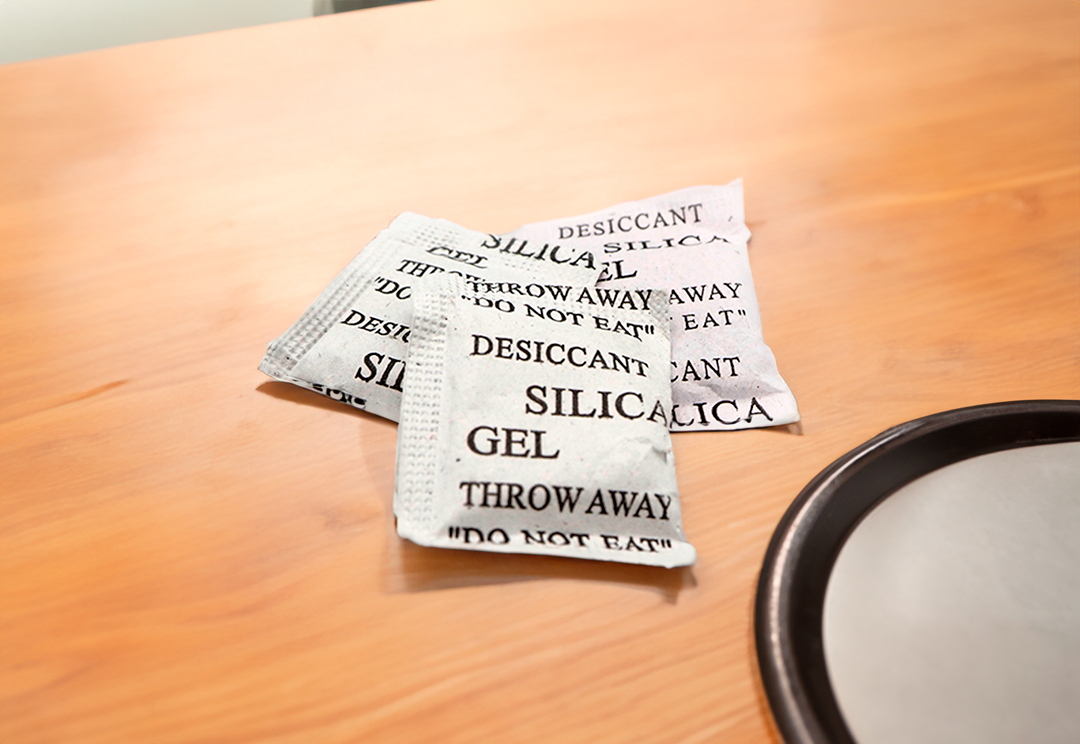

In the world of packaging, where product protection and preservation is essential, desiccant bags are a crucial innovation for maintaining the integrity of objects in transit and storage. These small but powerful bags offer an effective solution to combat moisture and spoilage that can affect sensitive products throughout their life cycle.

Imagine, a carefully manufactured product is about to be shipped over long distances or stored in variable conditions. The risk of moisture infiltration comes into play, which could cause irreparable damage such as corrosion, mold or even degradation of the product itself. This is where desiccant bags become the ultimate defense.

Our desiccant bags are designed with state-of-the-art technology to absorb moisture from the environment and create a dry and safe environment inside the packaging. Manufactured with high quality materials, these bags are highly resistant and capable of retaining absorbed moisture effectively. Its compact design allows for easy insertion into boxes, containers or wrappers, without taking up valuable packaging space.

The answer lies in its superior and long-lasting absorption capacity. Regardless of whether the product is in a humid environment or experiences drastic climate changes, our bags will stand firm in their mission to protect against the damaging effects of moisture. Whether you are packaging electronics, pharmaceuticals, dry food or industrial components, our desiccant bags are the perfect partner to safeguard quality and functionality.

Contact us and we will offer you a solution adapted to your needs.

Desiccant bags represent an essential solution to address moisture-related challenges in product packaging and transportation. Some of its distinctive features include:

We have three types of Desiccant Bags with different purposes to adapt to all kinds of conditions and needs of our customers.

advanced and effective for the protection of goods against humidity during transport in containers. This technology combines the absorbent properties of natural clay and calcium chloride to create a high-performance desiccant that keeps moisture at bay and ensures that products reach their destination in optimal condition.

The basis of these desiccant bags is natural clay, which acts as a highly efficient moisture absorber. Natural clay is able to capture and retain water molecules in its porous structure, preventing moisture from accumulating in the transport environment. In addition, the combination with calcium chloride enhances the desiccant capacity of the bags, as calcium chloride is known for its ability to absorb large amounts of moisture from the air.

The process of use is simple but effective. It is recommended to place approximately 1 kg of these bags per foot of container space. For example, for 20-foot containers, the use of 20 kg of desiccant bags is recommended, while for 40-foot containers, the use of 40 kg is recommended. This quantity optimizes the absorption capacity and guarantees complete protection against humidity inside the container.

It is important to note that uniform distribution of the desiccant bags within the container is critical for effective moisture control. Placing them strategically throughout the space ensures that all areas are covered and that there are no points of moisture accumulation. This intelligent arrangement maximizes the efficiency of the desiccant bags and provides a solid barrier against moisture during transport.

Advances in moisture protection in shipping have given rise to the new concentrated gel desiccant, a solution designed specifically for shipping containers that changes the way we approach moisture problems. This innovation transforms moisture into gel, providing exceptional effectiveness and surpassing the performance of traditional 2 kg desiccants.

Gel desiccant concentrate represents a comprehensive response to the challenges posed by moisture in shipping containers. Its ability to convert moisture into gel sets a new standard in ware absorption and protection.

Key advantages over traditional 2 kg desiccants include:

Under normal conditions, it is recommended to place 4 container gel bags in a 20-foot container and 8 in a 40-foot container. These quantities guarantee effective absorption and optimum protection against moisture inside the container.

Natural clay desiccant represents a highly effective solution for the protection of products against humidity in closed spaces or packaging. Designed to address moisture-related concerns, this type of desiccant is particularly valuable for chemicals, machinery, electronics and other items susceptible to the adverse effects of moisture.

This desiccant stands out for its ability to absorb moisture and maintain a dry environment inside closed spaces or packaging. Natural clay, with its porous structure, acts as a sponge that captures water molecules present in the surrounding air. In doing so, it prevents condensation, mold, mildew and other problems that can result from moisture.

The versatility of natural clay desiccant is evident in its applicability to a variety of industries and products. In the chemical industry, where moisture can alter the properties and efficacy of products, this desiccant acts as a guard against harmful effects. Similarly, in the machinery industry, where parts and components can corrode or deteriorate due to moisture, natural clay desiccant offers essential protection.

Electronics also benefit greatly from this type of desiccant. Electronic devices are particularly sensitive to moisture, which can cause short circuits and irreparable damage to internal components. The use of natural clay desiccants in the packaging of electronic products helps prevent these problems, ensuring that the devices reach the customer in optimal condition.

In case this solution does not perfectly fit the needs of your products or services you can always contact us directly and we will be happy to find the best alternative for you.